Bearing inspection

Within the total installation, the bearing is only a small part. But it is a hugely important component. If a bearing is defective, it can have major consequences. The production line may come to a standstill, with loss of production as a result.But also consequential damage to gears and shafts cannot be ruled out. Repairs often take a long time, with the result that production is down for longer.

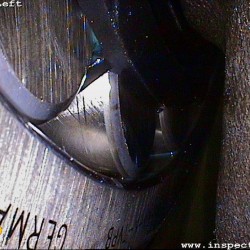

Endoscopy

With the help of endoscopes, we visualize the internal condition of the bearing. In this way, we carry out detailed research into pitting, spreading and cracks in the bearing. By detecting deviations at an early stage, further damage can be limited to a minimum and possible repairs can be planned. This means that expensive production losses and financial damage can be minimized.

Also, as a follow-up of a different vibration measurement, endoscopy is the ideal inspection method.In this way, we can locate the culprit without major intervention and a repair plan can be drawn up.