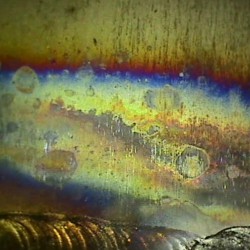

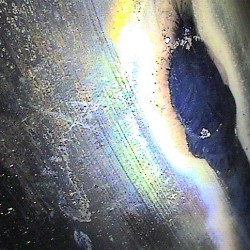

Visual inspection of RVIS

The proper functioning of a process plant depends on the quality of the welding in the pipe system. Although the weld looks good from the outside, it is very important that the connection is welded securely and meets the applicable standards.

Using special camera equipment, we can check the weld seam for defects on the pipe interior. We have various pan & tilt inspection cameras and video endoscopes for this visual inspection. By using these camera systems, we fully visualize the weld seam and digitally record concealed abnormalities in the welding.

Welding inspection report

Because we record the inspection on photo and/or video and this is processed in an extensive report, you have important documentation of your system. This is to ensure the safety, hygiene and functionality of your installation. Using visual camera systems (visual testing/VT) is therefore the most ideal inspection method for this.

Qualified welding inspection

Our qualified and certified inspectors (VT2 and/or VT-w2) carry out welding inspections in accordance with the welding specifications required by the client or the standards applicable in the industry. Performing a complete or random welding validation provides certainty for the future. All welding inspections comply with NEN EN ISO 9712.